10%短切玻璃纤维增强ABS 3D打印材料

产品简介

FusFun™ ABS-GF是一款专门为3D打印开发的ABS类耗材,同时加入了10%质量分数的玻璃纤维进行增强,与同类产品相比具有更低的气味性和优秀的尺寸稳定性。

物性表

测试项目 Property | 测试方法 Testing method | 典型值 Typical value |

密度 Density | ISO 1183 | 1.08 g/cm³ |

玻璃化转变温度 Glass transition temperature | ISO 11357 | 101°C |

熔融指数 Melt index | 250℃,2.16kg | 4 g/10min |

维卡软温度 Vicat softening temperature | ISO 306 | 106°C |

热变形温度 Determination of temperature | ISO 75:Method A ISO 75:Method B | 92°C (1.8MPa) 96°C (0.45MPa) |

拉伸断裂强度(X-Y) Tensile breaking strength | ISO 527 | 43.44±0.86 MPa |

断裂伸长率(X-Y) Elongation at break | 2.80±0.21 % | |

杨氏模量(X-Y) Young’s Modulus | 3213±82.78 MPa | |

拉伸断裂强度(Z) Tensile breaking strength | ISO 527 | 19.02±0.9 MPa |

杨氏模量(Z) Young’s Modulus | 2331±130 MPa | |

断裂伸长率(Z) Elongation at break | 1.28±0.32 % | |

弯曲强度(X-Y) Bending strength | ISO 178 | 66.21±0.42 MPa |

弯曲模量(X-Y) Bending Modulus | 2681±24.99 MPa | |

缺口冲击强度(X-Y) Charpy impact strength | ISO 179 | 8.17±0.66 KJ/㎡ |

试样打印参数:喷嘴大小0.4mm,喷嘴温度250°C,底板加热100°C,打印速度50mm/s,填充率100%,填充角度±45°

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 250°C, Bed temp 100°C, Print speed 50mm/s, Infill 100%, Infill angle ±45°

建议打印参数

喷头温度 Nozzle temperature | 250-270°C |

建议喷嘴大小 Recommended nozzle diameter | ≥0.2 mm |

建议底板材质 Recommended build surface | 玻璃、PEI膜或PC膜 Glass、PEI Film or PC Film |

底板温度 Build plate temperature | 100-110°C |

Raft间距 Raft separation distance | 0.16-0.18 mm |

冷却风扇 Cooling fan speed | 0-30% |

打印速度 Print speed | 30-120 mm/s |

回抽距离 Retraction distance | 1-5 mm |

回抽速度 Retraction speed | 1800-3600 mm/min |

建议支撑材料 Recommended Support Material | FusFree™ S-Multi Quick-Remove Support |

其他建议: 1. ABS类材料相比PLA,PETG等材料在打印过程中需要有较高的环境温度来帮助释放零件成型过程中的残余应力,在打印过程中请将打印机保持封闭状态,可以有效避免打印零件出现翘曲和开裂现象。如果设备具有加热腔功能,建议将加热腔温度设置在60-80°C之间。 2. 长期打开包装后的ABS-GF线材,如打印过程中发现打印质量下降,请将线材置于70-80℃条件下干燥4-6h。 3. 虽然FusFunTM ABS-GF与同类产品相比气味更小,但仍然建议在打印时将打印机放置在通风环境中。

Additional Suggestions: 1. Compared with PLA, PETG and other materials, ABS materials need a higher chamber temperature to help release the residual stress during the printing process. Please keep the printer chamber closed during the printing process. It can effectively avoid printed parts from warping and cracking. If the device has a heated chamber, it is recommended to set the temperature of heated chamber between 60-80°C. 2. If the ABS-GF filament has been unpacked for a long time and the printing quality starts to degrade during the printing process, please dry the filament at 70-80°C for 4-6 hours before printing. 3. Although FusFun™ ABS-GF has much less odor compared with similar products, it is still recommended to place the printer in a well-ventilated area during printing. | |

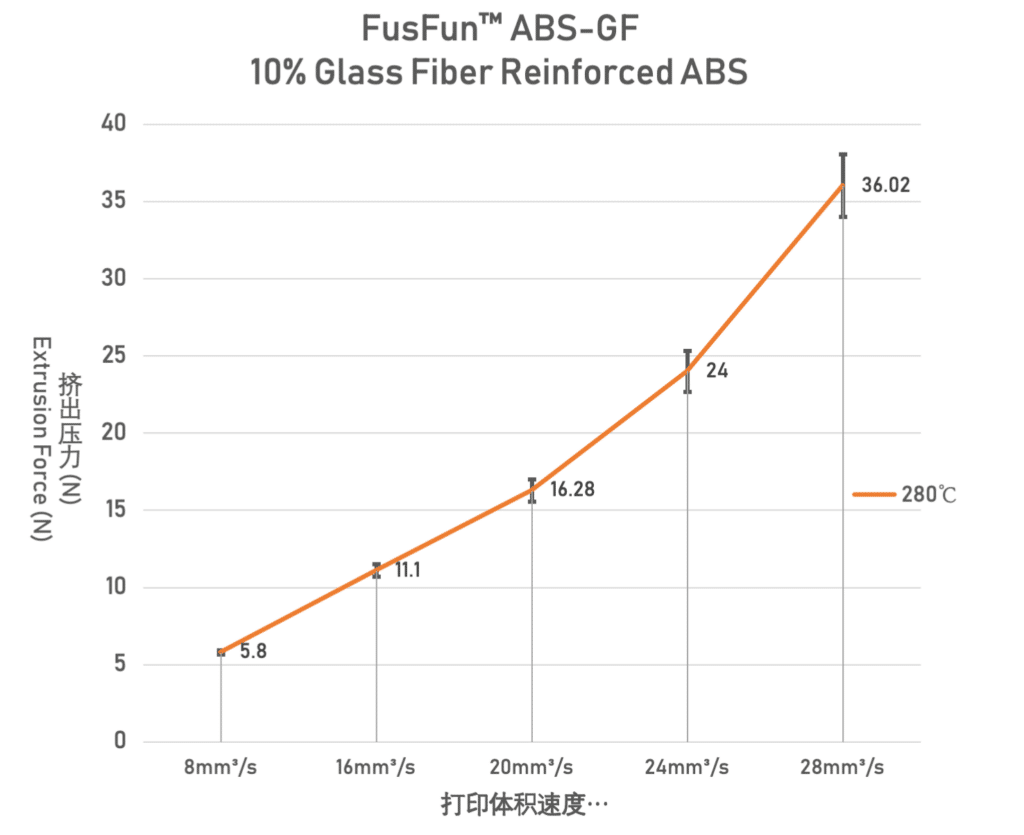

挤出压力与打印流量速度测试

测试参数:12mm长度铜制加热块,BMG挤出机,Phaetus硬化钢喷头,喷嘴大小0.4mm,层高0.2mm。

Test parameters: 12mm length brass heat block, BMG extruder, Phaetus Hardened Steel Nozzle, Nozzle size 0.4mm, Layer Height 0.2mm.