共挤包覆结构25%短切玻璃纤维增强高温尼龙3D打印材料。

产品简介

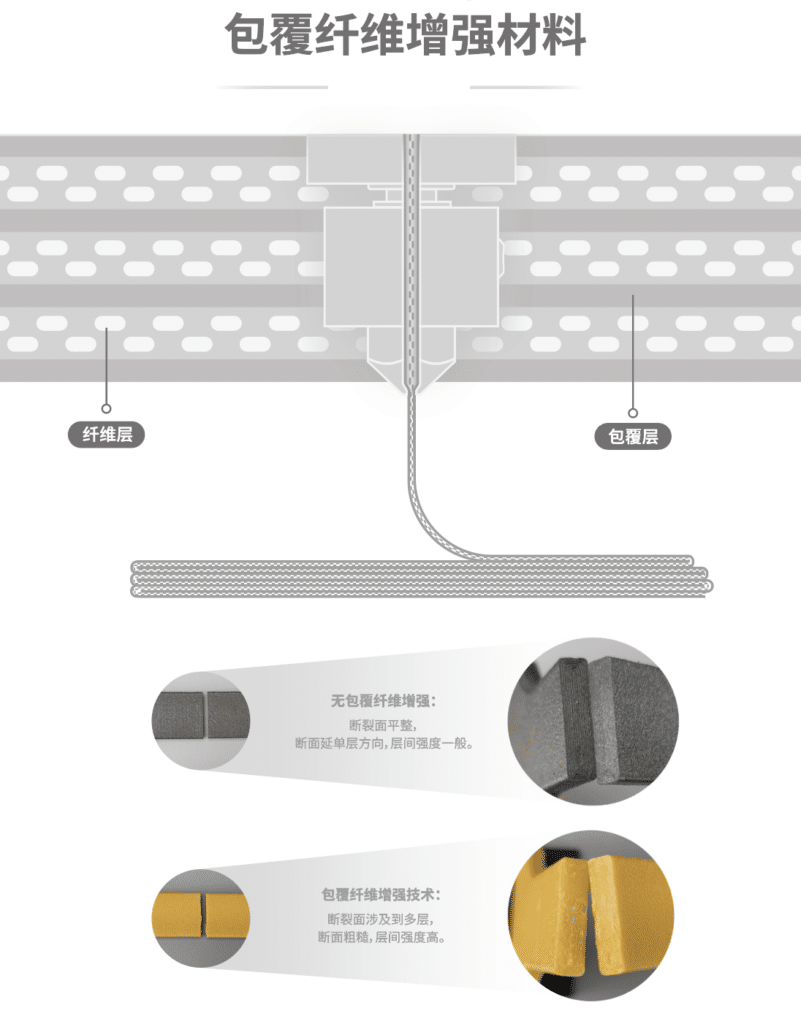

FusCoating™ NexPA-GF25是一款具有双层包覆结构的25%玻璃纤维增强高温尼龙3D打印线材。线材外层为高粘接强度的纯尼龙树脂,线材内芯为短切玻璃纤维增强的高温尼龙。FusCoating™ 3D打印包覆线材利用了高分子熔体在挤出过程中一般为层流运动的特性,线材在通过打印机喷头后仍能保持稳定的双层包覆结构,打印时的Z轴层间方向可以始终保持为外层的纯树脂之间粘接,大幅度提高了纤维增强类FDM材料的Z轴层间强度,同时25%填充含量的短切玻璃纤维又进一步提高了打印零部件件的整体机械性能与耐热性,非常适合打印薄壁类和高机械性能要求的零部件。

物性表

测试项目 Property | 测试方法 Test Method | 典型值 Typical value | ||

密度 Density | ISO 1183 | 1.29 g/cm³ | ||

饱和吸湿率 Water absorption | ISO 62: Method 1 | 1.99 % | ||

熔点 Melting Temperature | ISO 11357 | 237°C | ||

熔融指数 Melt index | 300°C, 2.16kg | 5.5 g/10min | ||

| 未退火 Unannealed | 退火后 Annealed | 退火后 饱和吸湿处理 Saturation hygroscopic treatment after annealed | |

热变形温度 Determination of temperature | ISO 75: Method A (1.80 MPa) | 79.2°C | 118.0°C | 96.9°C |

ISO 75: Method B (0.45 MPa) | 86.0°C | 195.5°C | 195.2°C | |

拉伸强度(X-Y) Tensile strength(X-Y) | ISO 527 | 96.82 ± 1.07 MPa | 105.01 ± 1.14 MPa | 72.12 ± 0.83 MPa |

拉伸模量(X-Y) Young’s modulus(X-Y) | 5400.57 ± 227.21 MPa | 5729.78 ± 301.68 MPa | 4587.29 ± 206.31 MPa | |

断裂伸长率(X-Y) Elongation at break (X-Y) | 2.92 ± 0.13 % | 2.41 ± 0.05 % | 6.48 ± 0.38 % | |

弯曲强度(X-Y) Bending strength (X-Y) | ISO 178 | 161.99 ± 2.39 MPa | 168.20 ± 4.76 MPa | 102.64 ± 1.18 MPa |

弯曲模量 (X-Y) Bending modulus (X-Y) | 5402.49 ± 123.21 MPa | 5957.97 ± 95.66 MPa | 3228.36 ± 252.82 MPa | |

缺口冲击强度 (X-Y) Charpy impact strength (X-Y) | ISO 179 | 12.55 ± 0.86 KJ/㎡ | 7.59 ± 0.81 KJ/㎡ | 22.02±1.47 KJ/㎡ |

拉伸强度 (Z) Tensile strength (Z) | ISO 527 | 65.40 ± 2.99 MPa | / | / |

拉伸模量(Z) Young’s modulus (Z) | 4150.79 ± 80.04 MPa | / | / | |

断裂伸长率(Z) Elongation at break (Z) | 1.90 ± 0.15 % | / | / | |

试样打印参数:喷嘴温度340℃,底板加热80℃,打印速度45mm/s,填充率100%,填充角度±45°

退火条件:100℃退火8小时

Specimens printed under the following conditions: Nozzle temp 340℃, Bed temp 80℃, Print speed 45mm/s, Infill 100%, Infill angle ±45°

Post-processing: 100°C Annealing 8 hours

建议打印参数

喷头温度 Nozzle Temperature | 300-340℃ |

建议喷嘴大小 Recommended Nozzle Diameter | 0.4-1.0mm |

建议底板材质 Recommended build surface treatment | PEI底板或者涂抹PVP固体胶 PEI or Coating with PVP glue |

底板温度 Build plate temperature | 70-80℃ |

Raft间距 Raft separation distance | 0.08-0.12 mm |

冷却风扇 Cooling fan speed | 关闭 Off |

打印速度 Print speed | 30-120 mm/s |

回抽距离 Retraction distance | 1-3 mm |

回抽速度 Retraction speed | 1800-3600 mm/min |

建议支撑材料 Recommended support material | FusFree™ S-PAHT Quick-Remove Support |

其他建议: Additional Suggestions:

1. 尼龙材料非常容易吸收环境内的水分,吸湿后打印会出现拉丝,挤出有气泡等现象,降低打印质量。建议您打开FusCoatingTM NexPA-GF25真空铝箔袋包装后立即将线材放入干燥盒内(湿度控制在15%以下)进行打印。不用的线材请放回原包装铝箔袋内密封保存。 Nylon material is very easy to absorb moisture within the environment, and printing after absorbing moisture will result ozzing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below 15%) immediately after opening the FusCoatingTM NexPA-GF25 vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage.

2. 材料受潮后会出现打印拉丝增多,挤出有气泡,打印表面质量粗糙等现象。请将线材放入80-100℃烘箱内干燥4-6h,即可恢复FusCoatingTM NexPA-GF25的打印质量。 After the material is damp, there will be more printing ozzing, bubbles extruded and rough printing surface. Please dry the filament in an oven at 80-100℃ for 4-6h to restore the printing quality of FusCoatingTM NexPA-GF25.

3. 建议选用Phaetus硬化钢及以上等级喷嘴,可以有效提高打印质量,建议加热块厚度不小于12mm。 It is recommended to use hardened steel and above grade nozzles made by Phaetus, which can effectively improve the print quality. Besides, it is recommended that the thickness of the heating block is longer 12mm.

4. 打印完成后可以对打印件进行退火处理,可以进一步提高FusCoatingTM NexPA-GF25打印件的强度,退火条件:80-100℃温度下放置4-8小时后取出即可。 After the printing is completed, the FusCoatingTM NexPA-GF25 printed part can be annealed to further improve the strength of print part. Annealing conditions: leave printing part in an oven at 80-100℃ for 4 to 8 hours and cool to room temperature naturally. | |

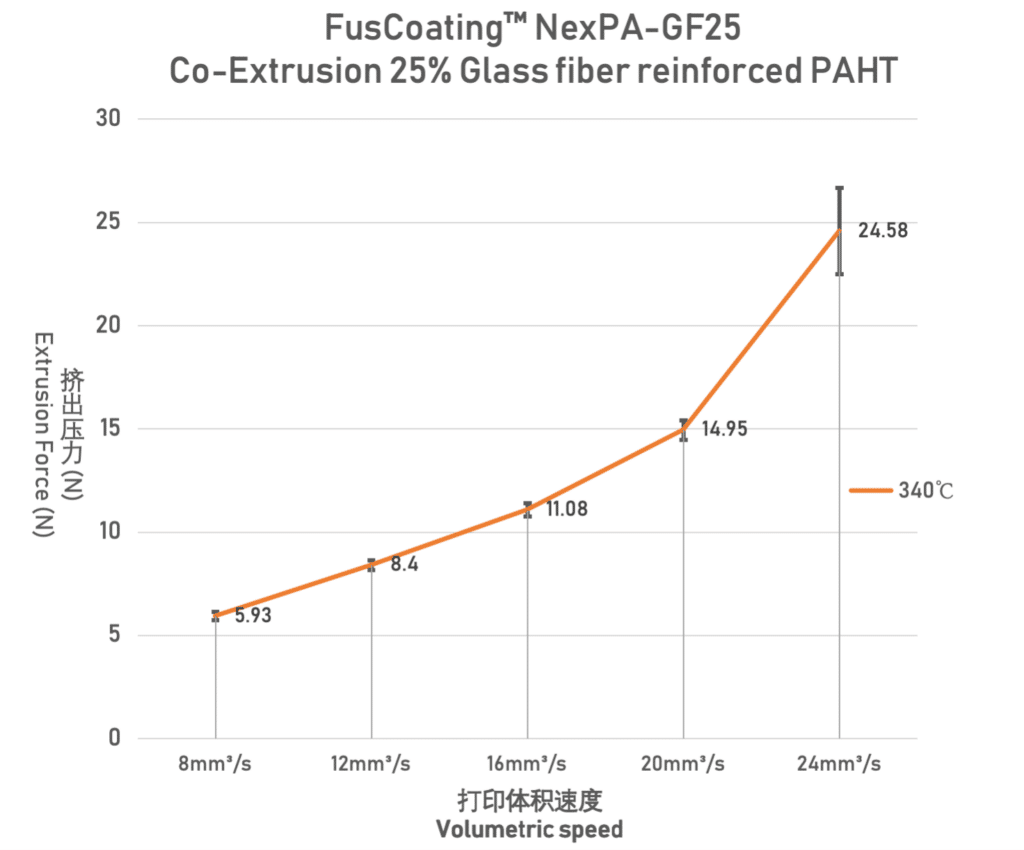

挤出压力与打印速度测试

测试参数:12mm长度铜制加热块,BMG挤出机,Phaetus硬化钢喷头,喷嘴大小0.4mm,层高0.2mm。

Test parameters: 12mm length brass heat block, BMG extruder, Phaetus Hardened Steel Nozzle, Nozzle size 0.4mm, Layer Height 0.2mm.