发泡型ASA 3D打印材料

产品介绍

FusFun™ ASA-Aero专为航模、船模、无人机等领域研发,提供了一种轻质的3D打印耗材。ASA-Aero 通过在打印过程中温度调节,控制材料的发泡倍率,使喷头挤出的耗材密度可以在一定范围内调节,降低模型重量,最佳情况下可降至普通ASA打印模型的40%左右;打印件表面的磨砂质感也可以一定程度上降低层纹现象。

物性表

测试项目 Test Item | 测试方法 Test Method | 典型值 Typical Value |

密度 Density | ISO 845 | 1.03 g/cm³ |

熔融指数 Melt index | ISO 1133 250°C,2.16kg | 1.5 g/10min |

热变形温度 Determination of temperature | ISO 75:Method A ISO 75:Method B | 55°C (1.8 MPa) 70°C (0.45 MPa) |

断裂拉伸强度(X-Y) Tensile strength at Break (X-Y) | ISO 527 | 8.25±0.15 MPa |

断裂伸长率(X-Y) Elongation at break (X-Y) | 11.52±0.58 % | |

杨氏模量(X-Y) Young’s Modulus | 593.99±24.34 MPa | |

断裂拉伸强度(Z) Tensile strength at Break (Z) | ISO 527 | 7.86±0.14 MPa |

断裂伸长率(Z) Elongation at break (Z) | 5.54±0.28 % | |

杨氏模量(X-Y) Young’s Modulus | 457.94±20.84 MPa | |

弯曲强度(X-Y) Bending strength | ISO 178 | 14.31±1.66 MPa |

弯曲模量(X-Y) Bending Modulus | 544.92±74.44 MPa | |

缺口冲击强度(X-Y) Charpy impact strength | ISO 179 | 2.29±0.13 KJ/㎡ |

试样打印参数:流量50% 喷嘴大小0.4mm,喷嘴温度250°C,底板加热100°C,打印速度45mm/s,填充率100%,填充角度±45°

Specimens printed under the following conditions: Flow rate 50%,Nozzle size 0.4mm,Nozzle temp 250°C, Bed temp 100°C, Print speed 45mm/s, Infill 100%, Infill angle ±45°

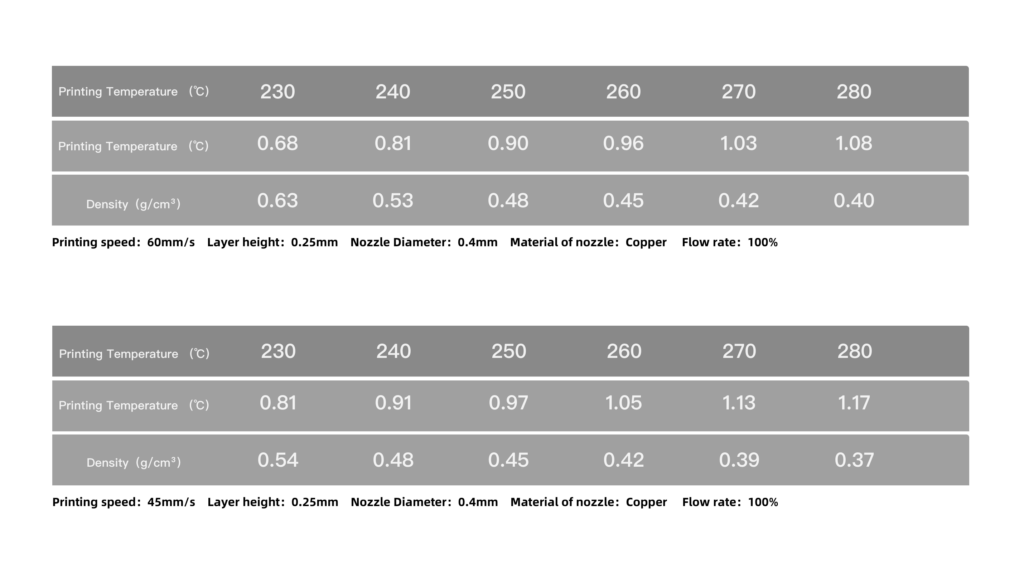

ASA-Aero LT 打印温度对发泡的影响

建议打印参数

喷头温度 Nozzle temperature | 240-280°C |

建议喷嘴大小 Recommended nozzle diameter | ≥0.4mm |

建议底板材质 Recommended build surface | 玻璃、PEI膜或涂抹PVP固体胶 PEI Film or Coating with PVP glue |

底板温度 Build plate temperature | 80-110℃ |

Raft间距 Raft separation distance | 0.18-0.2mm |

冷却风扇 Cooling fan speed | 0-50% |

打印速度 Print speed | 30-90 mm/s |

其他建议: · 由于ASA-Aero采用了“在线发泡”的技术,耗材在喷头内部受热后就会迅速膨胀,造成难以避免的拉丝现象,切片软件中的回抽设置无法起到明显的作用,甚至建议关闭回抽设置。 · 由于ASA类材料具有较高的玻璃化转变温度,在打印时需要一定的环境温度(40-70°C),以释放打印件的内应力减少翘曲;在无保温的条件下,打印单层薄壁模型时,建议使用直径0.6mm及以上喷嘴打印,以保证强度和减小收缩现象产生。 · 在打印ASA-Aero时,请将打印机在封闭的情况下放置在通风环境中。

Additional suggestions: · Since ASA-Aero adops the ‘on-demand foaming’ technology, the filament will continue to expand in the nozzle after being heated during the printing process. Therefore, it will cause unavoidable stringing during the nozzle movement. Even adjusting the retraction setting in the slicing software cannot solve this problem. Based on the above, it is recommended to turn off the retraction setting. · Because ASA materials have a high glass transition temperature, a certain ambient temperature(40-70°C) is required during printing to release the internal stress of the printed parts and reduce warping. When printing thin-walled models without any form of insulation, it is recommended to use nozzles with a diameter of 0.6mm or more to ensure the strength of printed parts and reduce shrinkage. · When printing with ASA-Aero filaments, please place the enclosed printer in a ventilated environment. | |