阻燃PC 3D打印材料

产品简介

FusForce™ PC-FR是一款优秀的防火材料,以聚碳酸酯为基材,通过添加磷系阻燃剂,使PC具有优秀的自熄性能,阻燃等级可达UL94 V-0级(0.8mm)。相比于添加卤素阻燃剂的材料,FusForce™ PC-FR燃烧后不会释放大量烟雾和有毒气体,更加安全环保,同时仍然保留了聚碳酸酯优秀的机械性能和耐热性。

物性表

测试项目 Property | 测试方法 Test Method | 典型值 Typical Value | |

密度 Density | ISO 1183 | 1.19 g/cm³ | |

玻璃化转变温度 Glass transition temperature | ISO 11357 | 115°C | |

熔融指数 Melt index | 250°C,2.16kg | 12 g/10min | |

| 未退火 Unannealed | 90°C退火4h Annealed at 90°C for 4h | |

热变形温度(X-Y) Heat deflection temperature (X-Y) | ISO 75:Method A ISO 75:Method B | 102°C (1.8MPa) 107°C (0.45MPa) | 106°C (1.8MPa) 110°C (0.45MPa) |

拉伸屈服强度(X-Y) Tensile yield strength (X-Y) | ISO 527 | 58.09±0.68 MPa | 61.50±0.66 MPa |

屈服点伸长率(X-Y) Elongation at Yield (X-Y) | 4.30±0.07 % | 4.07±0.08 % | |

杨氏模量(X-Y) Young’s modulus (X-Y) | 2532.29±85.81 MPa | 2754.86±61.29 MPa | |

拉伸断裂强度(X-Y) Tensile breaking strength (X-Y) | 50.28±0.94 MPa | 58.65±1.17 MPa | |

断裂伸长率(X-Y) Elongation at break (X-Y) | 7.06±1.49 % | 5.06±0.75 % | |

拉伸断裂强度(Z) Tensile breaking strength (Z) | ISO 527 | 50.39±1.91 MPa | 50.10±1.62 MPa |

杨氏模量(Z) Young’s modulus (Z) | 2649.30±145.33 MPa | 2462.30±224.55 MPa | |

断裂伸长率(Z) Elongation at break (Z) | 2.65±0.21 % | 2.82±0.20 % | |

弯曲强度(X-Y) Bending strength (Z) | ISO 178 | 83.99±0.76 MPa | 90.73±0.35 MPa |

弯曲模量(X-Y) Bending modulus (X-Y) | 1906.71±78.22 MPa | 1857.86±128.77 MPa | |

缺口冲击强度(X-Y) Charpy impact strength (X-Y) | ISO 179 | 13.43±1.26 kJ/㎡ | 9.49±0.76 kJ/㎡ |

UL阻燃等级 UL Flame-retardant Grade | |||

0.4mm厚度 0.4mm thickness | UL94 | V-2 | |

0.8mm厚度 0.8mm thickness | V-0 | ||

2.0mm厚度 2.0mm thickness | 5VB | ||

试样打印参数:喷嘴大小0.4mm,喷嘴温度255°C,底板加热110°C,腔体温度55℃,打印速度50mm/s,填充率100%,填充角度±45°

退火条件:90℃,退火4小时

Specimens printed under the following conditions: Nozzle size 0.4mm, Nozzle temp 255°C, Bed temp 110°C, Chamber temp 55°C, Printing speed 50mm/s, Infill 100%, Infill angle ±45°.

Annealing conditions: The specimens were annealed at 90°Cfor 4h.

建议打印参数

喷头温度 Nozzle temperature | 250-270°C |

建议喷嘴大小 Recommended Nozzle diameter | ≥0.2mm |

建议底板材质 Recommended build surface treatment | PEI底板 PEI Film |

底板温度 Build plate temperature | 110-120°C |

腔体温度 Chamber temperature | 80-100°C |

Raft间距 Raft separation distance | 0.16-0.18 mm |

冷却风扇 Cooling fan speed | Off |

打印速度 Printing speed | 30-120 mm/s |

回抽距离 Retraction distance | 1-3 mm |

回抽速度 Retraction speed | 1800-3600 mm/min |

其他建议: 1. PC打印温度较高,对水分较敏感,在打印过程中将线材放入干燥盒内,相对湿度控制在15%以下,可有效减少拉丝、表面粗糙等现象。如果耗材已吸潮,可以使用烘箱在100-110℃进行4小时的烘干处理。 2. 使用PC打印的模型在90℃环境下退火4h,可有效释放内应力,延长使用寿命。

Additional suggestions: 1. PC filament is sensitive to moisture and can easily have stringing during printing. To reduce the stringing and surface roughness effectively, keep your filament in a dry box and control relative humidity to below 15%. If the filament has absorbed moisture already, dry the filament in an oven at 100-110°C for 4 hours. 2. It is recommended to anneal models printed with PC at 90℃ for 4h, which can effectively release the internal stress and prolong the service life. | |

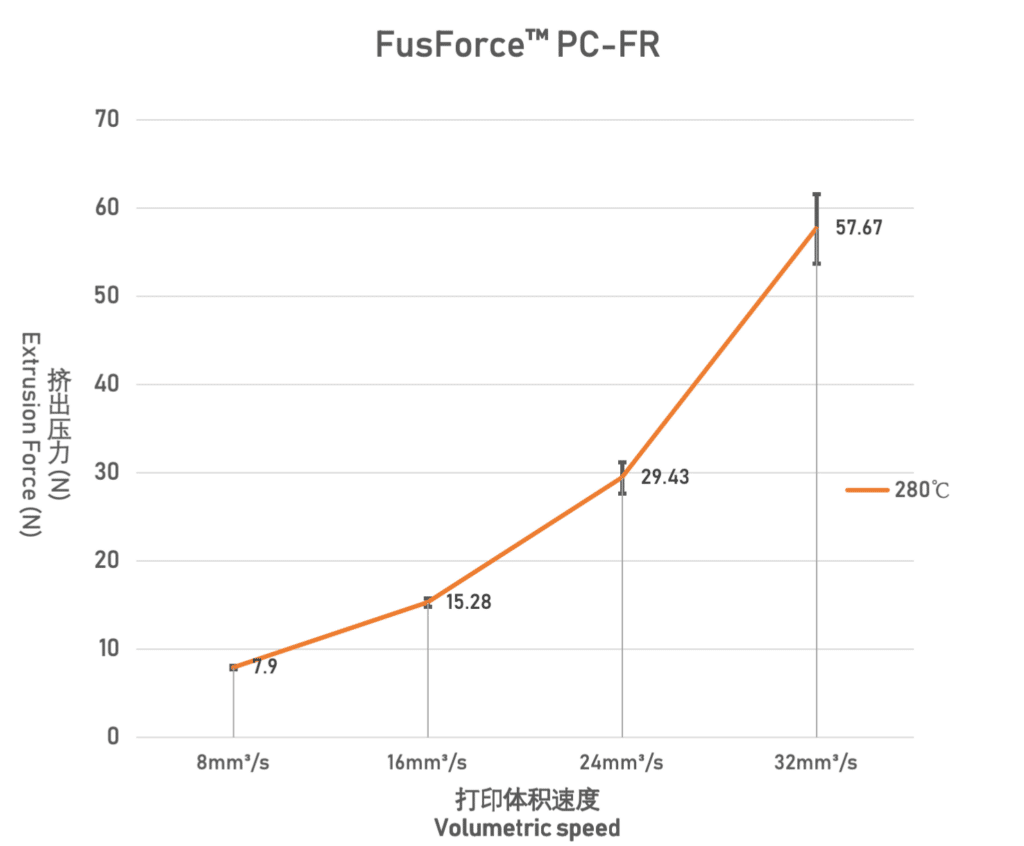

挤出压力与打印流量速度测试

测试参数:12mm长度铜制加热块,BMG挤出机,Phaetus硬化钢喷头,喷嘴大小0.4mm,层高0.2mm。

Test parameters: 12mm length brass heat block, BMG extruder, Phaetus Hardened Steel Nozzle, Nozzle size 0.4mm, Layer Height 0.2mm.