ToughPETG-HF

产品简介

FusFun™ ToughPETG-HF是一款专为FDM开发的韧性改良PETG,通过提高材料流动性,使其具有极佳的高速打印性能。同时相比PLA具有更好的力学强度与耐热性。

物性表

测试项目 Property | 测试方法 Testing method | 典型值 Typical value |

密度 Density | ISO 1183 | 1.27 g/cm³ |

玻璃化转变温度 Glass transition temperature | ISO 11357 | 80°C |

熔融指数 Melt index | 220℃,2.16kg | 7 g/10min |

热变形温度 Determination of temperature | ISO 75:Method A ISO 75:Method B | 65°C(1.80MPa) 70°C (0.45MPa) |

拉伸屈服强度(X-Y) Tensile yield strength(X-Y) | ISO 527 | 44.23 ± 0.64 MPa |

屈服伸长率(X-Y) Yield elongation(X-Y) | 4.19 ± 0.06 % | |

杨氏模量(X-Y) Young’s modulus(X-Y) | 1821.82 ± 49.41 MPa | |

拉伸断裂强度(X-Y) Tensile breaking strength(X-Y) | 21.92 ± 3.98 MPa | |

断裂伸长率(X-Y) Elongation at break(X-Y) | 14.04 ± 7.77 % | |

杨氏模量(Z) Young’s modulus(Z) | 1955.67 ± 179.30 MPa | |

拉伸断裂强度(Z) Tensile breaking strength(Z) | 42.70 ± 0.51 MPa | |

断裂伸长率(Z) Elongation at break(Z) | 4.51 ± 0.82 % | |

弯曲强度(X-Y) Bending strength(X-Y) | ISO 178 | 71.40 ± 0.74 MPa |

弯曲模量(X-Y) Bending modulus(X-Y) | 1895.07 ± 36.19 MPa | |

缺口冲击强度(X-Y) Charpy impact strength(X-Y) | ISO 179 | 16.39 ± 2.16 KJ/㎡ |

试样打印参数:喷嘴大小0.4mm,喷嘴温度240°C,底板加热80°C,打印速度45mm/s,填充率100%,填充角度±45°

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 240°C, Bed temp 80°C, Print speed 45mm/s,

Infill 100%, Infill angle ±45°

建议打印参数

喷头温度 Nozzle temperature | 230-260°C |

建议喷嘴大小和材质 Recommended nozzle diameter and nozzle material | 0.2-1.0mm 铜制喷头 |

建议底板材质 Recommended build surface | 玻璃、PEI膜或涂抹PVP固体胶 Glass、PEI Film or Coating with PVP glue |

底板温度 Build plate temperature | 70-80°C |

Raft间距 Raft separation distance | 0.2-0.25 mm |

冷却风扇 Cooling fan speed | 0-50% |

打印速度 Print speed | 30-300 mm/s |

回抽距离 Retraction distance | 1-5 mm |

回抽速度 Retraction speed | 1800-3600 mm/min |

建议支撑材料 Recommended support material | FusFreeTM S-Multi Quick-Remove Support Material |

其他建议: 1. ToughPETG-HF和PC材质底板粘接非常牢固,在打印较大底面时,可以适当调大模型首层和底板的间距。 | |

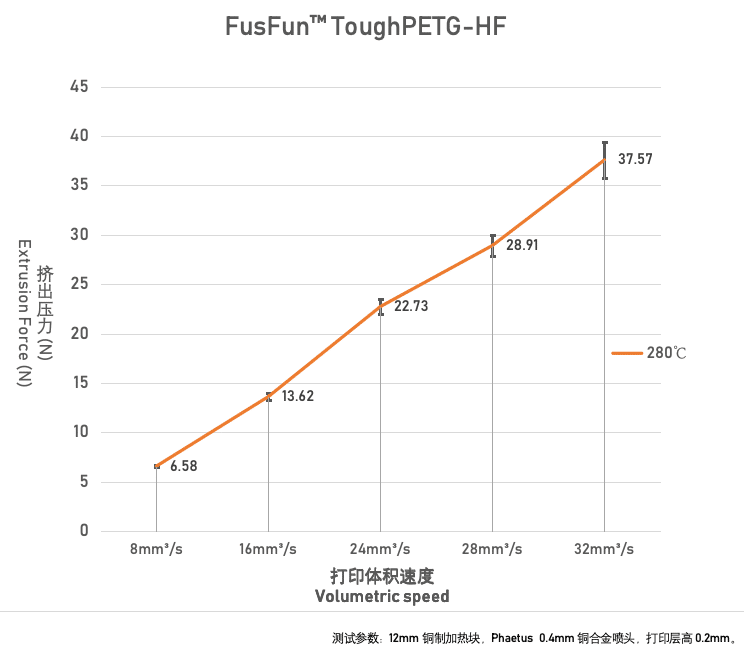

挤出压力与打印流量速度测试